Page 49 - ESJ – ENERGY STORAGE JOURNAL

P. 49

FEATURE: RECYCLING

market in end-of-life EVs will start to grow,

we can and will scale up our recycling activi- “Someone said that the recycling of lithium batteries

ties.” would be a $23 billion business in 2025. Actually

Canadian miner turns LiB recycler there’s room for a lot of people – and I think it’s

It was almost coincidental that American reached that flexion point where it’s going to be a

Manganese already had the bones of a process

for recycling lithium batteries — thanks to its runaway trade over the next decade.” – Larry Reaugh

mining processes.

It began in Arizona, when this Surrey,

Canada-based manganese mining company

developed a very low-cost process for recov-

ering the low-grade manganese it was min-

ing –without using the heat that conventional

processing required. Instead, it used reagents

combined with ‘unit operations’.

“We were actually able to get very com-

petitive with conventional processing meth-

ods — we did a pre-feasibility study and so

on — but manganese prices started dropping

and the project was no longer feasible,” says

chief technical officer Zarko Meseldzija. “So

we got patents for the process, but we put it

on the shelf.

“A few years later, we saw the trend in EVs,

the electrification of everything, and with the

help of Kemetco Research, we realized this

could work for cathode materials which con- material so it reduces the number of steps in-

tain cobalt, nickel, manganese, aluminium and volved in the manufacture of the cathode,” he

lithium. We did some initial bench testing and says.

the theory proved out — it was spot on. We Meseldzija says he’s aware of other labora-

got out the pure cathode material with 100% tories doing the same thing — but they have

recovery.” had their own patent granted in record time.

Meseldzija accepts that in an industrial pro- “It was done in 13 months — they normally

cess the results are unlikely to be so impressive take up to five years, so it was a great achieve-

because of impurities in the feedstock and so ment and shows it’s a hot topic,” he says.

on, but he still reckons on 90% recovery. One of the most important aspects is reduc-

“And the material comes back as a cathode ing the number of steps required in the re-

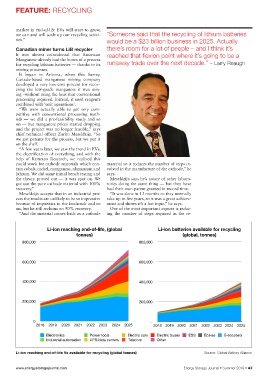

Li-ion reaching end-of-life, (global Li-ion batteries available for recycling

tonnes) (global, tonnes)

800,000 800,000

600,000 600,000

400,000 400,000

200,000 200,000

0 -

2018 2019 2020 2021 2022 2023 2024 2025 2018 2019 2020 2021 2022 2023 2024 2025

Electronics Power tools Electric cars Electric buses ESS Ebikes E-scooters

Industrial automation UPS/data centers Telecom Other

Li-ion reaching end-of-life Vs available for recycling (global tonnes) Source: Global Battery Alliance

www.energystoragejournal.com Energy Storage Journal • Summer 2019 • 47